asme b31.3 charpy impact test|a106b charpy testing : factories Hi Every one We have been discussing about para 323.3.4 ASME B31.3 2008, we all understand that it is required to reduce the test temperature for sub-size impac B31.3 _ Temperature reduction for sub-size charpy impact specimens - Pipelines, Piping and Fluid Mechanics engineering - Eng-Tips

Resultado da Hot latina gets her sweaty cunt fucked. 7 min Gody80 -. 2. 3. 62 Delfina Suárez FREE videos found on XVIDEOS for this search.

{plog:ftitle_list}

web27 de dez. de 2021 · 105K subscribers. Subscribed. Share. 95K views 2 years ago. Playback da canção "Enquanto Você Louva" da cantora Larissa Pires lançado pela Todah Music .

charpy impact testing guidelines

Per B31.3 A106B is exempt from impact testing at -20F for thicknesses up to 1/2". This comes from Table A1 showing A106B as a Curve B material and referencing Table .In B31.3, Table 323.3.1 specifies the location and number of impact tests for .I need to qualify a welding procedure in accordance with Section IX, with the .

In B31.3, Table 323.3.1 specifies the location and number of impact tests for base material and fabrication welds to be completed, and to record the data. It says nothing about .

a106b charpy testing

If you don’t know how API 570 Certification scheme, See API 570 Certification Instruction IMPACT TESTING The inspector should be able to: a) Determine the minimum metal temperature of a material (MDMT), which is exempt from impact testing (ASME B31.3, Section 323.2.2, Figure 323.2.2A & Table A-1). b) Determine the minimum required Charpy V-notch . Hi Every one We have been discussing about para 323.3.4 ASME B31.3 2008, we all understand that it is required to reduce the test temperature for sub-size impac B31.3 _ Temperature reduction for sub-size charpy impact specimens - Pipelines, Piping and Fluid Mechanics engineering - Eng-Tips Current B31.3 Toughness Testing Requirements • Table 323.2.2 Austenitic Stainless Steels: B- 4 Base metal and weld metal deposits shall be impact tested in accordance with para. 323.3. • When impact testing is required by Table 323.2.2, paragraph 323.3.4 and sub-paragraphs require Charpy impact testing at a temperature not higher than the

Minimum Design Metal Temperature & Charpy V-Notch Impact Test. ASME B31.3 has specified the design minimum temperature of -20°F [-29°C] for which ASTM A335 P11 is normally suitable without impact testing requirements. However, in engineering practices, the use of ASTM A335 Gr. P11 shall be limited at the minimum temperature of 0°F [-18°C].

ASME B31.3, 2014 년 판에 . 최대 획득가능 샤르피 표본 (maximum obtainable Charpy specimen) 이 새김눈을 따라 2.5 mm (0.098 in.) 미만의 . 323.3 Impact Testing Methods and Acceptance Criteria) (찰나충격 시험방법과 . hi guys, may i need the help regarding to impact test for stainless steel A182 Gr316, the input is code construction ASME B31.3, design temperature is -90 to 100 degree C. so need i do the impact test for PQR during qualification stage. Iimpact testing for ASME B31.3 A106-B,P1-P1 Pipe as per ASME B31.3 construction code does not typicaly require impact testing, down to -20f. Below -20f you should be using A333 (low temp) Piping with impact testing down to -38 Rememer this is minimum code requirements and customer requirements may require more stringent criteria.

ASME Presentation Charpy Impact Test - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. This document provides the agenda for a meeting of the ASME B31.3 Process Piping Committee to take place from April 18-20, 2016. It includes announcements, presentations, publications approved for inclusion in B31.3-2016, requests for interpretation, . I need to qualify a welding procedure in accordance with Section IX, with the supplementary essential variables for Charpy impact testing as required by ASME B31.3. The base material is 304 SS, with production material thickness ranging from .

custom grain moisture meter lds 1g

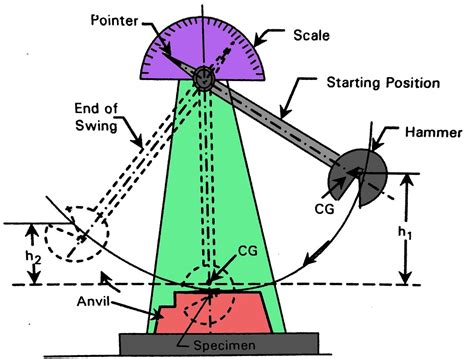

What Is the History of the Charpy Impact Test? The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This method assesses the energy absorbed by a standard notched specimen when it fractures under an impact load.

ASME B31.3 INTERPRETATIONS Interpretation 25-02 Subject: Para. 302.3.5(c), Stress Due to Sustained Loads (B31.3-2012) Date Issued: April 14, 2014 Percentage Crystallinity and Lateral Expansion in Charpy Impact test. Brittle fractures are shiny and crystalline, and ductile fractures are dull and fibrous. . For example, in ASME B31.3, instead of specifying an impact value, the lateral extension of threaded materials and steels with a UTS greater than 656 N / mm2 should be 0.38 mm.4 • Rapid adiabatic heating of test samples during Charpy impact testing at ultra-low temperatures makes current Charpy testing requirement invalid for ensuring material toughness . • Any sort of testing in liquid helium is difficult to accomplish, expensive, and not readily available. • Testing in LN2 has not been demonstrated to shed light on properties at -452F. IF you are working with the High Pressure Section (Chapter IX) of ASME B31.3, then you will need to acheive the values shown in Table K323.3.5 unless otherwise stated in your Engineering Design. . K323.3.4 Test Temperatures. For all Charpy impact tests, .

I bring the following doubt about the table Table 323.2.2 Requirements for low temperature toughness tests for metals ASME B31.3 2020 As we can see, it has a review in table A-3 (b) (2020) where I understand that if I have a certified welding consumable with impact test I can exempt said test in the WPS qualification, for example: ASME B31.3 • Impact Testing (Paragraph 323.2.2, Paragraph 323.3.1) - For most carbon steels, impact testing during the welding procedure qualification was changed from being required for the weldment for design minimum temperatures below -29°C (-20°F). The new edition requires

As such, ASME recently has changed the impact testing requirements for many spools, flanges, and piping products. . ASME VIII Div. I and ASME B31.3, consider carbon steels—any ferrous material having 0.29 to . Bob Rasooli explains impact test requirement as per ASME B31.3 for process piping which is API 570 piping inspector and API SIFE (source inspection fixed equ. ASME B31.3 claims that no Charpy Test is required for A106 Gr. B if the design temperature is equal or above -29ºC, and I have doubts if this can also apply to ASME B31.8, since it does not specify. . temperature and the potential impact on fracture performance at low temperatures. Whenever the minimum design temperature is below −20°F .

Typically these steels are exempt from impact testing for minimum design temperatures -29°C (-20°F) per ASME B31.3 for thicknesses up to 12.7 mm (0.5 in). It has been found that the cause of the unexpected low toughness was a combination of changes in the chemical composition of the steel due to changes in the steel making practices.

Abstract. Carbon steel components (Flanges, Fittings and Piping) have been reported with low impact test results. Some have failed during hydrotest and start-up as well as in-service. Steel grades that have shown problems complying with impact test requirements are ASTM/ASME A105, ASTM/ASME A234 Gr. WPB and ASTM/ASME A106. ASTM A350 LF2. .

In our July 2012 issue we discussed “ASME Section VIII UHA-51 Impact Test: Changes Affecting Cryogenic Vessels Made from Austenitic Stainless Steel”. This article prompted an email last month from reader Walter Detlef of Linde – Kryotechnik. In his email, Walter made assertions that raised two interesting questions not covered in the original article. Welding – Impact Testing Both B31.3 and B31.12 require toughness testing/charpy impact testing on weld samples of P8 materials (Example: S304/L and 316/L), and result in a minimum lateral expansion greater than 0.015 inches (0.38 mm). NDE – Examination Requirements

3.11.8 IMPACT TESTING OF WELDING PROCEDURES AND TEST PLATES OF FERROUS MATERIALS. 3.11.8.1 Impact Tests. (a) For steel vessels of welded construction, the impact toughness of welds and heat-affected zones of procedure qua-lification test plates and vessel test plates (production impact test plates) shall be determined as required in this . What Is ASME B31.1. ASME B31.1, often referred to as the Power Piping Code, is typically used in power generation and industrial plants, and specifically designed for high-pressure boiler systems and steam systems. This code is highly explicit and governs the design, construction, and testing of piping systems associated with boilers and steam .Impact Testing and Toughness Requirements for Pressure Vessels; ASME Section VIII, Divisions 1 & 2 A Practical, Case Study-based Training Program Led by: . repairs, and alterations of pressure equipment following ASME, B31, NBIC, API, DOT and various International Codes and Standards. He also has extensive experience in the area ofASME B31.3-2006 (Revision of ASME B31.3-2004) Process Piping ASME Code for Pressure Piping, B31 AN AMERICAN NATIONAL STANDARD Three Park Avenue • New York, NY 10016

Resultado da Segredos de Nós Dois SIMPLIFICADA - Experimente o Banana Cifras e tenha acesso grátis a milhões de cifras para tornar suas sessões musicais ainda mais incríveis. Menu principal Pesquisar música Gêneros Repertórios Histórico Afinador online Cadastre-se Entrar

asme b31.3 charpy impact test|a106b charpy testing